Best Energy independently developed

2026-01-04

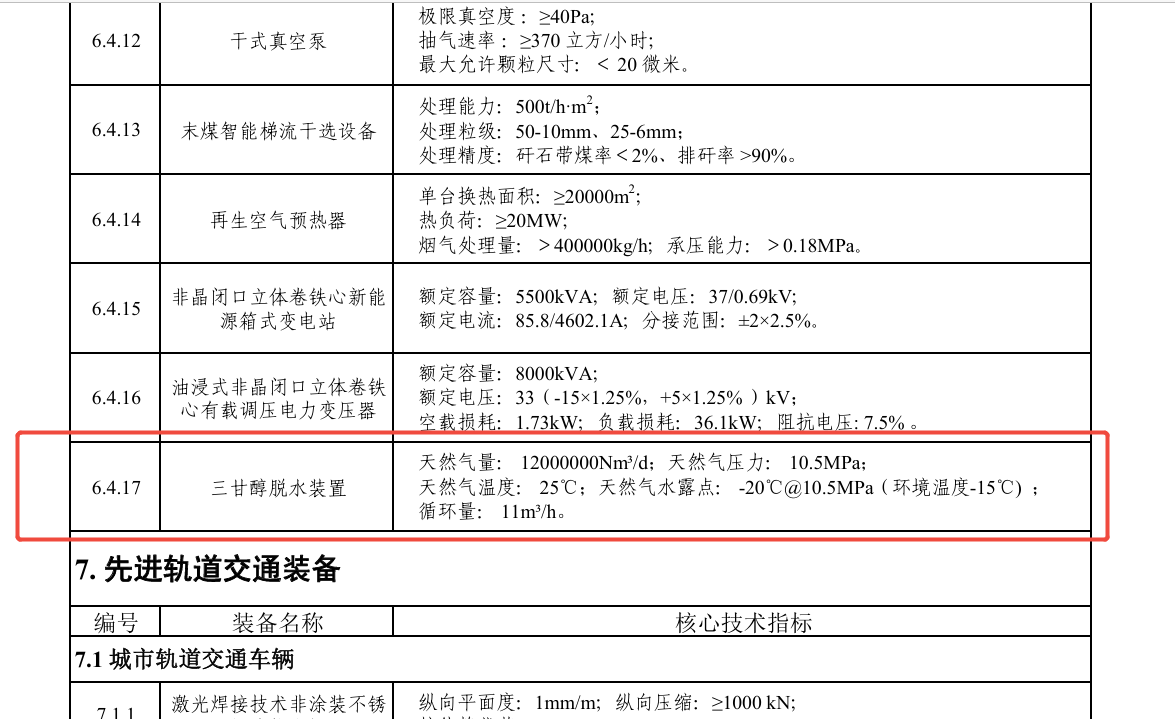

This revision of the catalog strictly followed the requirements of the "Notice of the Ministry of Finance, the Ministry of Industry and Information Technology, and the China Banking and Insurance Regulatory Commission on Further Deepening the Pilot Work of the Insurance Compensation Mechanism for the First Set of Major Technical Equipment." It underwent multiple rigorous stages, including local recommendations, industry assessments, and expert reviews, ultimately selecting a batch of major technical equipment with independent intellectual property rights, significant technological innovation, and broad market application prospects. The inclusion of Best Energy's " Triethylene Glycol Dehydration Unit" not only affirms the company's long-term technological innovation but also provides strong policy support for its market promotion and industrial application.

As a high-end intelligent equipment developed to meet the needs of deep dehydration of high-pressure, high-flow natural gas, the Best Energy triethylene glycol dehydration unit excels in core technical indicators and performance advantages:

Large processing capacity : The daily natural gas processing capacity is up to 12 million standard cubic meters, which can meet the dehydration needs of large gas fields and long-distance pipeline hub stations.

High operating pressure : Design pressure reaches 10.5MPa, adapting to high-pressure natural gas processing technology, improving system integration and safety.

Excellent dehydration depth : It can stably reduce the natural gas water dew point to -20℃ (ambient temperature -15℃) under an operating pressure of 10.5MPa, effectively preventing pipeline ice blockage and corrosion, and ensuring the safe and efficient operation of long-distance pipelines.

Intelligent operation and high efficiency and energy saving : The system adopts advanced intelligent control and optimization algorithms to achieve precise adjustment of glycol circulation (circulation rate 11m³/h) , which significantly reduces energy consumption and solvent loss of the unit and improves the economic efficiency and stability of operation.

To overcome key technical challenges such as high-pressure deep dehydration process simulation, efficient regeneration, intelligent control, and system integration, Best Energy leveraged its years of experience in energy equipment R&D to assemble a dedicated technical team to tackle these challenges, achieving a harmonious balance between high reliability, high adaptability, and low operating costs for its equipment. This technological achievement has been fully validated in multiple projects in oil and gas fields and national-level gas storage facilities , setting an industry benchmark in various complex application scenarios with its stable performance, efficient energy consumption control, and professional technical services.

As an innovative enterprise focusing on the energy equipment field, Best Energy has always regarded technological innovation as its core driving force for development, and has been continuously cultivating the key equipment track for natural gas purification and treatment. In the future, the company will take this inclusion in the national first (set) equipment catalog as an opportunity to further accelerate the market promotion and industrialization iteration of this equipment, deepen collaborative cooperation with upstream and downstream enterprises in the industry, and continue to increase R&D investment to promote the transformation and application of more core technological achievements, thus contributing more to the high-quality development of my country's energy equipment manufacturing industry and ensuring national energy security and green development strategies.