Petrobest showcases its core compressed air energy storage products at the 3rd Long-Duration Energy Storage Conference

2025-09-09

The China Long-Duration Energy Storage Conference is a professional offline conference in China that focuses on the application and development of various long-duration energy storage technologies. This year's conference will be held from September 10th to 12th at the Dongwu Kaiyuan Mingdu Hotel in Huzhou, Zhejiang Province. Recently, Best Energy Equipment (Tianjin) Co., Ltd. (hereinafter referred to as "Best Energy"), a national-level manufacturing single-product champion enterprise specializing in energy solutions, will showcase its core products, including compressed air energy storage cyclone separators, dechlorination devices, and high-temperature, high-pressure, large-diameter key control valves, at the exhibition. We sincerely invite you to attend, provide guidance, and discuss cooperation.

Founded in 2002, Best Energy is located in Jingqing Industrial Park, Wuqing District, Tianjin, on the Beijing-Tianjin corridor. In 2010, it wholly established Tianjin Better Fluid Control Valve Co., Ltd., and in 2016, it wholly acquired Beijing OHZEC Petroleum Engineering Co., Ltd. It is an energy solutions company with core technologies that integrates equipment manufacturing, design consulting, and engineering contracting.

Best Energy has long been committed to the development, design, manufacturing, installation and service of energy equipment such as long-distance natural gas pipelines, urban gas transmission and distribution, oil and gas field and gas storage ground engineering, compressed air energy storage, hydrogen energy storage and transportation, CCUS devices, residual pressure power generation, and molten salt energy storage.

Tianjin Flowbetter Control Valve Co., Ltd.'s axial flow regulating valves have won the titles of National Manufacturing Single Champion Product and National Specialized, Refined and Innovative Product . Its high-pressure bidirectional axial flow regulating valves have been selected as one of the first (sets) of major technical equipment by the National Energy Administration . The company is a national high-tech enterprise and a joint research and development unit for the localization of key valves in pressure regulating devices under the major science and technology project of CNPC led by the National Energy Administration ; a joint research and development unit for the localization of large-diameter axial flow regulating valves for the national high-flow metering and verification stations of the China Oil and Gas Pipeline Network Group ; and a joint research and application unit for compressor anti-surge valves organized by the West-East Gas Pipeline Company . It is also a member of the China General Machinery Industry Association Valve Branch and the China Electromechanical Integration Control Valve Branch.

At this conference, Best Energy will focus on showcasing its compressed air energy storage cyclone separators, dechlorination devices, and key valves for large-diameter, high-temperature, and high-pressure compressed air energy storage .

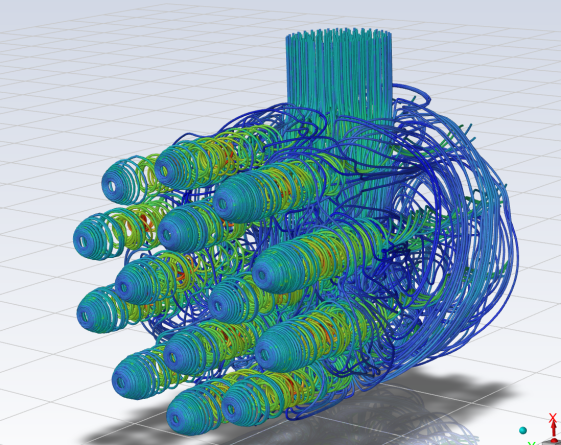

Compressed air energy storage well site cyclone separator

Cyclone separators are efficient, fast, and economical particle and droplet separation devices. Their performance is improved through optimized structural design, control of overall pressure drop, adaptation to gas volume, and enhancement of removal efficiency. The process design is adjusted for power generation conditions to ensure operation at 30-110% of the power generation load, while avoiding temporary functional failures caused by flow rate deviations from thresholds under low load conditions in energy storage power stations, thus ensuring long-term, stable, and efficient operation of the device.

Compressed air energy storage dechlorination device

For the chlorine-rich environment of salt cavern gas storage, the presence conditions, concentration and corrosion rate of chloride ions in the salt cavern are analyzed. Combined with the operating conditions of compressed air energy storage and power generation in the salt cavern, including process requirements such as sliding pressure, variable load, maximum allowable pressure drop and residual chlorine concentration, the overall engineering design is completed.

The system incorporates advanced technologies such as system planning, resistance optimization, and corrosion resistance to achieve independent research, design, and manufacturing. It effectively controls the chloride ion concentration in the process gas from the gas extraction source. The system is adapted to various dimensions, including salt cavern energy storage power station system design, plant site planning, and equipment performance.

The dechlorination unit is highly integrated and skid-mounted, designed to remove chloride ions from process gas and reduce corrosion rates. It guarantees a chloride ion concentration ≤50ppm and a system pressure drop ≤200kPa. Performance load range is guaranteed: 30%~110%.

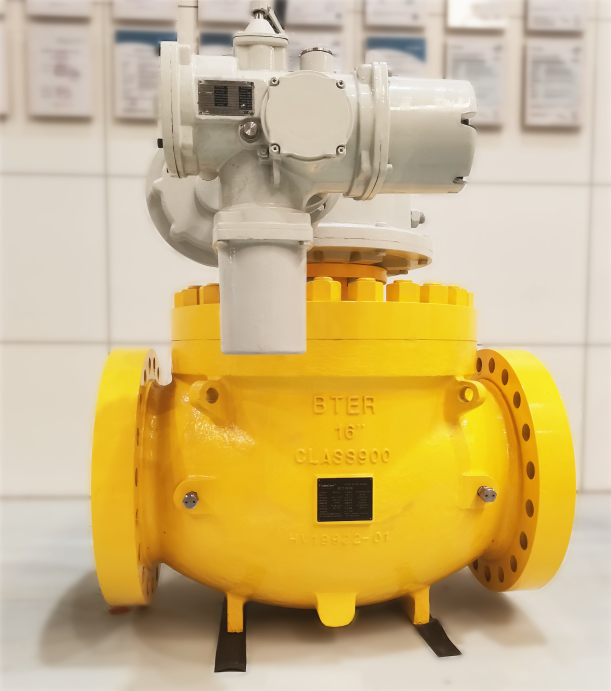

Compressed air energy storage high temperature, high pressure, large diameter key valves

We have developed, designed, and manufactured key control valves for compressed air energy storage that are characterized by large diameter, high pressure (~CL2500), high temperature (~400℃), high precision, low pressure loss, and fast response speed.

Compared with the Globe-type control valve, the high-temperature and high-pressure axial flow control valve reduces pressure loss by 40% and increases flow capacity by 35%; the bidirectional axial flow control valve can be selected for bidirectional flow conditions.

The top-mounted on/off ball valve features an alloy seal that is corrosion-resistant and erosion-resistant, ensuring reliable sealing (Class VI sealing standard), extremely low flow resistance, an on-mounted structure that allows for online maintenance, and a compact, small size.

The top-mounted regulating ball valve features a non-clogging orifice plate design; parallel orifice plate configuration; multi-stage and multi-flow path pressure reduction; high control precision; low pressure loss; greater flow capacity; and a maximum adjustment ratio of 300:1.

The pneumatic safety shut-off valve is suitable for high-pressure, zero-leakage conditions. It features a fully balanced axial flow structure with low pressure loss, can use pipeline gas as a power source, and has automatic shut-off protection functions for overpressure/underpressure and remote emergency shut-off functions.

Compressor anti-surge valves are selected in different structural forms depending on operating conditions such as pressure, temperature, and pressure difference.

Axial flow anti-surge valves are suitable for high pressure and large differential pressure conditions. The axial flow design has low flow resistance and large flow capacity. The fully balanced structure has a VI leakage rate, low vibration and low noise. It is equipped with a multi-spring double-acting pneumatic actuator, which can act quickly and operate reliably.

The shut-off anti-surge valve is suitable for medium-pressure and medium-differential-pressure conditions. It adopts the Globe low-inlet and high-outlet flow-opening design, and the top-mounted design facilitates maintenance. Multi-stage labyrinth-type throttling cages can also be customized for high-differential-pressure and low-noise applications.

The butterfly-type anti-surge valve is suitable for low-pressure and small-differential-pressure conditions. Its triple eccentric design ensures tight closure, and its compact structure allows for rapid 90° rotation.

High temperature and high pressure axial flow control valve

High temperature and high pressure large diameter top-mounted electric ball valve

High temperature and high pressure large diameter top-mounted pneumatic ball valve

compressor anti-surge valve

Best Energy cordially invites you to attend the meeting for communicate

Welcome to register

The 3rd China Long-Duration Energy Storage Conference 2025

Scan the QR code to participate now