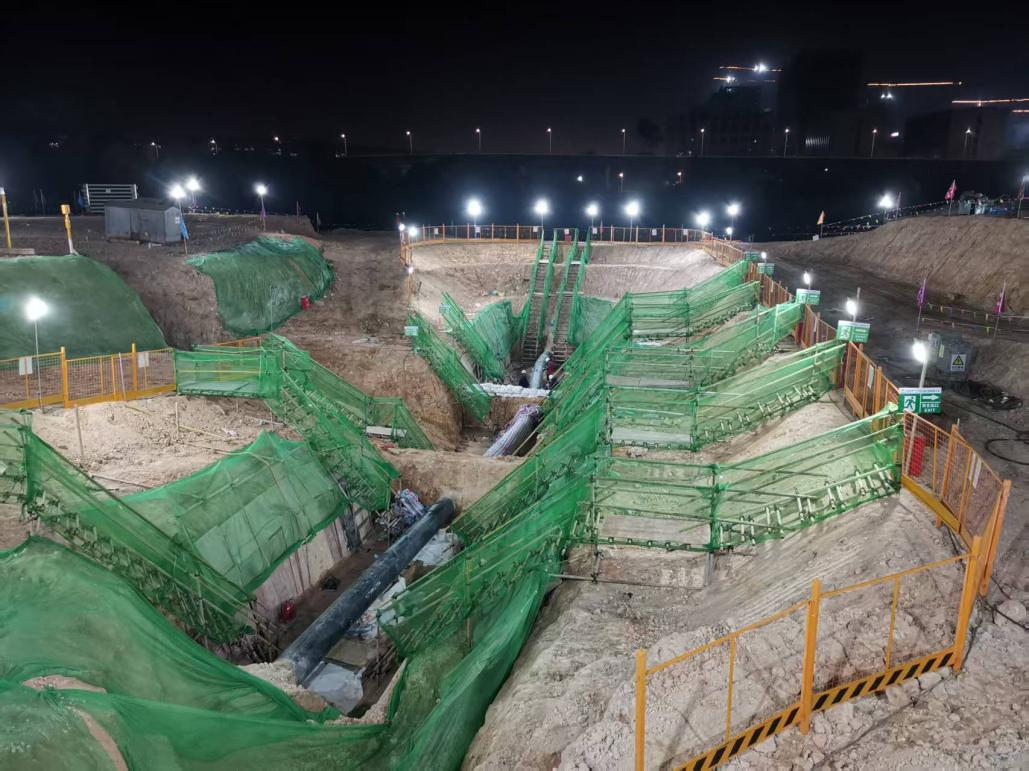

On June 27, 2019, our company won the bid for this Design-Build General Contracting Project tendered by Xiamen Road & Bridge Group, undertaking the full-process scope of work. The total length of the relocated and reconstructed pipelines is approximately 27 km. The project broke ground on December 3, 2019, and was put into operation on January 31, 2021.

High-pressure Pipelines:

●The rerouted Sinopec product oil pipeline measures 12.186 km in length, with a diameter of 355.6 mm and a design pressure of 10 MPa. Its designed annual transmission capacity for crude oil and product oil is 3.8 million tons.

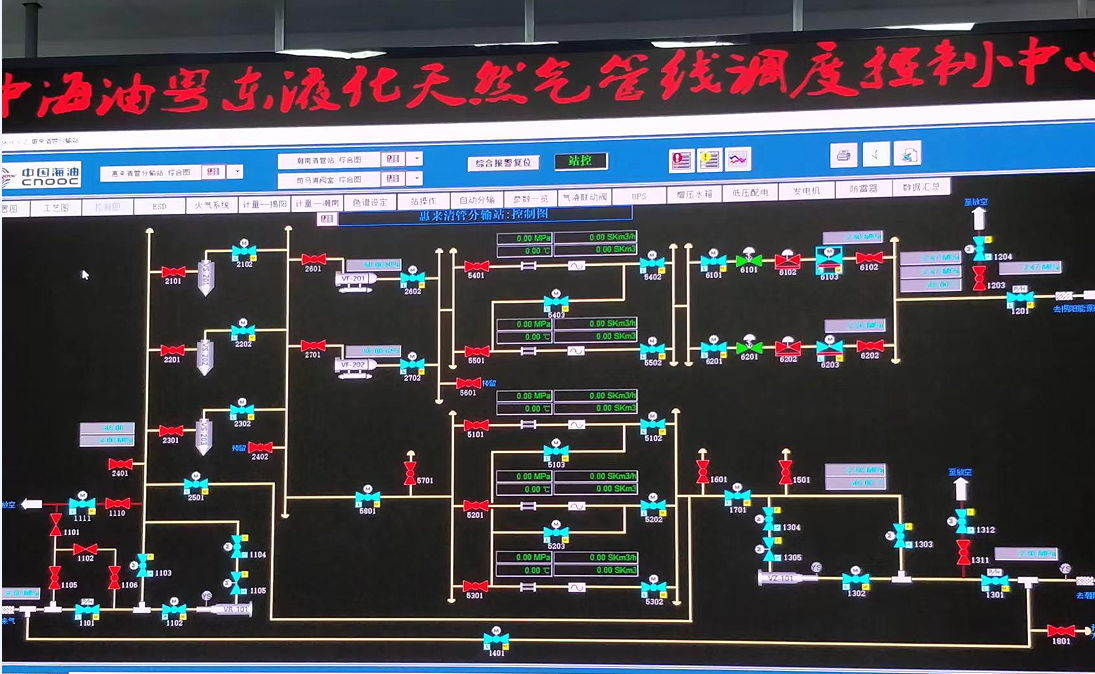

●The rerouted CNOOC LNG pipeline is 7.3 km long, with a diameter of D406.4 mm and a design pressure of 7.5 MPa.

●The rerouted China Resources natural gas pipeline has a length of 5.7 km, a diameter of DN600 and a design pressure of 4 MPa.

All the above pipelines are laid along the Shenyang-Haikou Expressway and its surrounding areas in accordance with the corresponding design parameters.

Medium-pressure Pipelines:

This part covers the relocation and reconstruction of the Xinglin and Guankou sections, as well as the connection of the Anren Boulevard section. With a diameter of DN300, a design pressure of 0.4 MPa and a total length of approximately 2 km, the original pipelines are decommissioned simultaneously to ensure transmission safety.