HOME

> PERFORMANCE DISPLAY

> ENGINEERING PROJECT MANAGEMENT

> Upgrading Project for Control Center of Hebei Natural Gas Company Limited

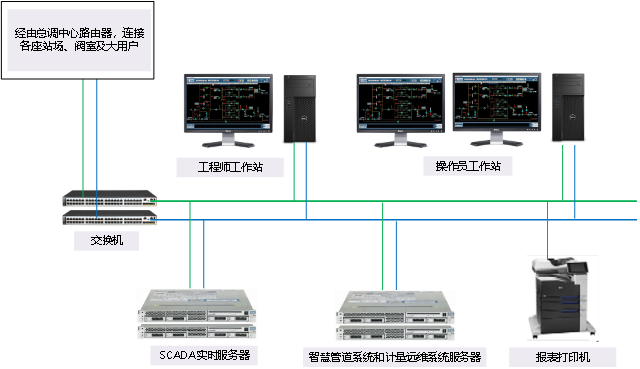

Comprehensively upgrade the existing control center of Hebei Natural Gas Co., Ltd., construct a new SCADA system, large-screen display system, operator station system, intelligent dispatching system and simulation system for the control center, and optimize the communication network between the control center, station sites and valve chambers.

For the emergency command center, add a new command center large-screen display and touch control platform, renovate the existing voice communication equipment, and build a new emergency command system. Integrate key production data, emergency vehicles and equipment, as well as emergency resources to provide real-time operation data and on-site video for emergency command, and improve the emergency response capability for sudden risks..User: Hebei Natural Gas Company Limited